Innovative electronics production

StarLine production is based on an integrated approach to the customer needs.

Special attention is paid to the storage conditions of electronic components which correspond to international standards and quality tests of the issued products.

StarLine provides the following types of equipment testing:

climatic;

electrostatic;

resistance to conductive interference;

resistance to radio interference;

radiated interference.

We also provide the services in 3D modeling and production of casings from various types of plastic and silicone.

We provide the services in graphic and industrial design from idea creation, prototyping to design of packaging and related advertising materials.

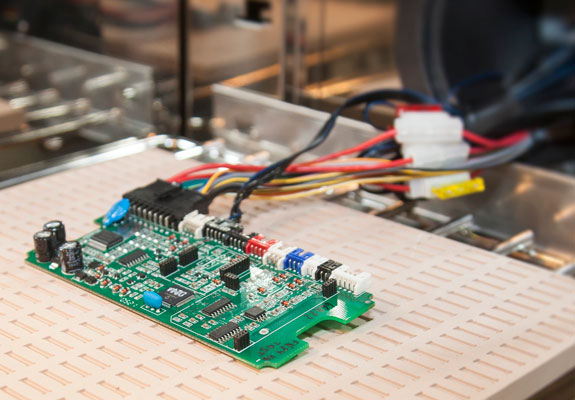

Maximally automated production

Maximally automated production

Process automated quality control

Process automated quality control

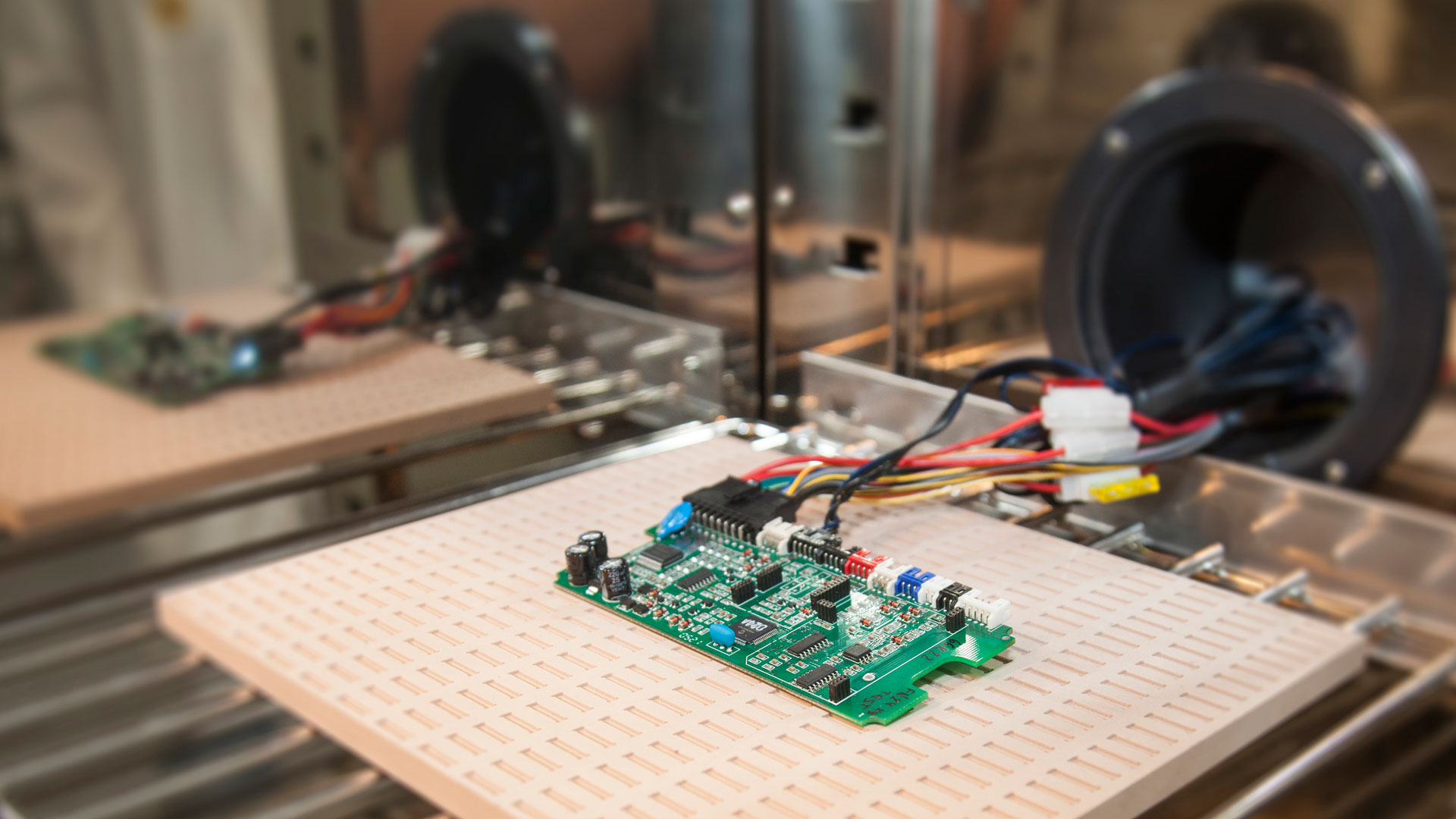

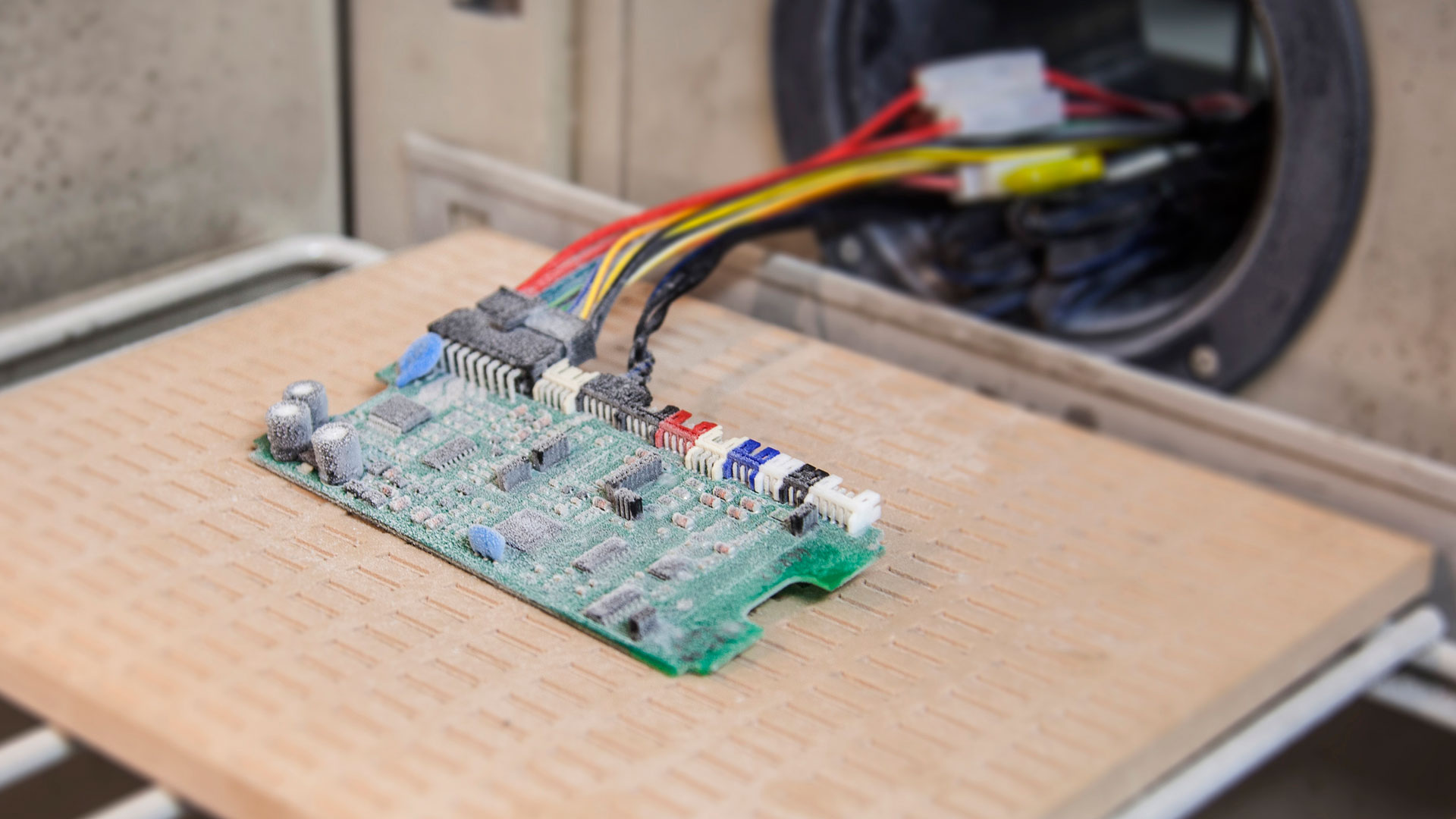

Climate chamber

Climate chamber

StarLine PRODUCTION

Product testing

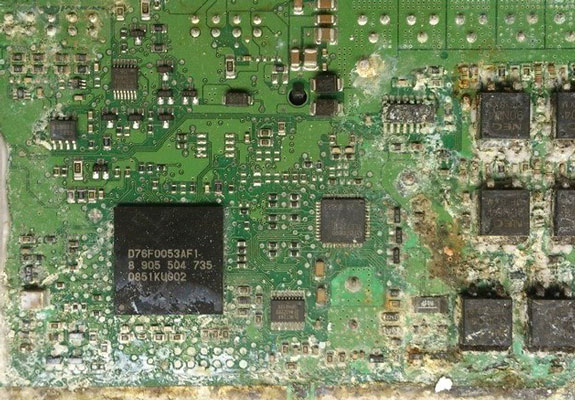

Product testing at temperatures from −75 to +180 °C and humidity from 0 to 98%

Detection of potential defects and their elimination

Storage of components

Storage of components

StarLine PRODUCTION

Correct storage of components

ESD protection of components

Adherence and control of temperature and humidity modes

Dry storage cabinets

Dry storage cabinets

StarLine PRODUCTION

Correct storage of components

ESD protection of components

Adherence and control of temperature and humidity modes

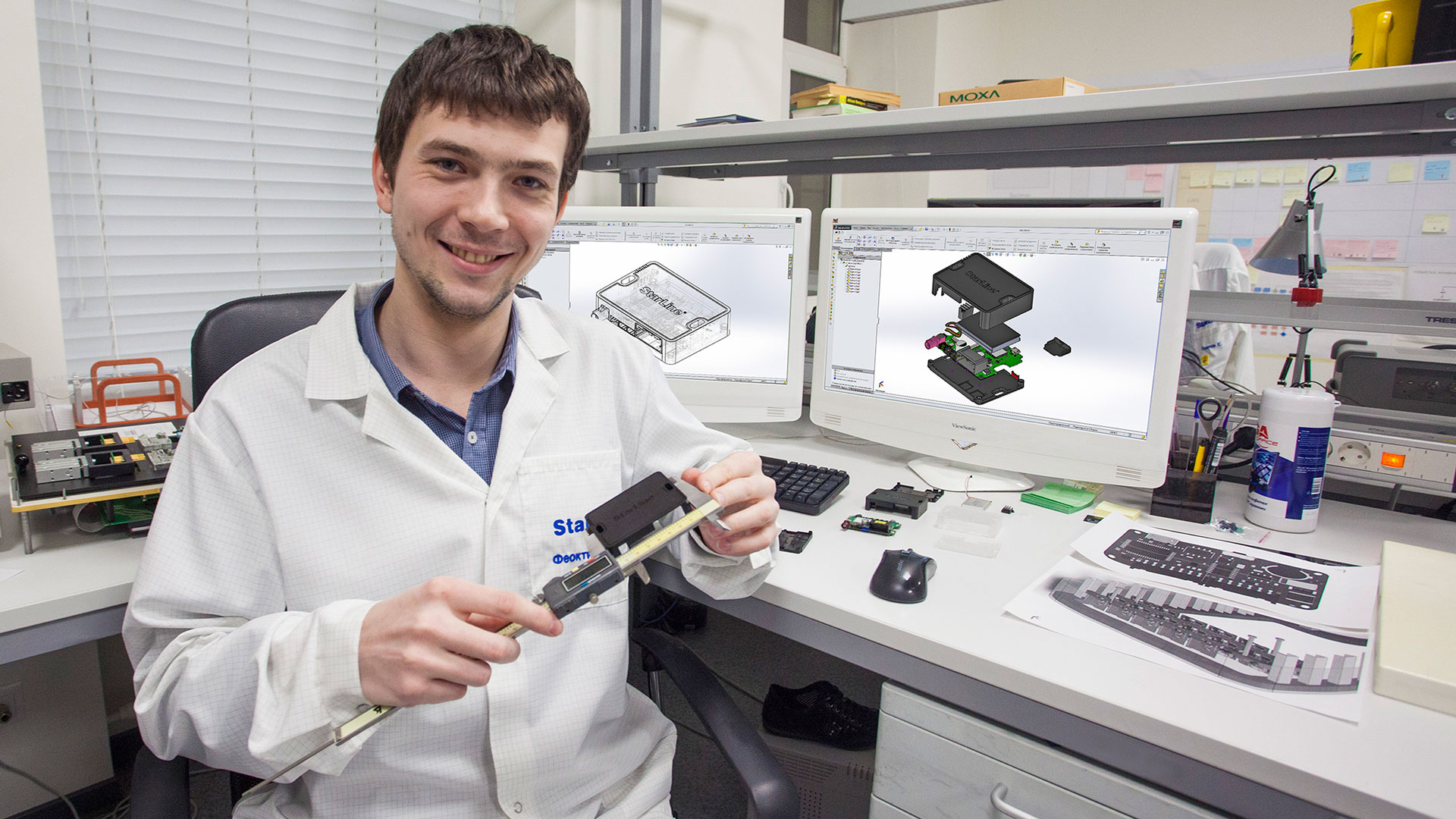

3D modeling and housing production

3D modeling and housing production

StarLine PRODUCTION

3D modeling and housing production

Computer mechanical modeling

Prototyping with the aid of 3D printer

Mass production of enclosures high quality

Design of packaging and printed materials

Design of packaging and printed materials

StarLine PRODUCTION

Design of packaging and a full range of printed materials

Use of packaging which closely matches the product dimensions — logistics optimization

«Self-selling» packaging

Design in the customer corporate style

Русский

Русский